Originally published on fastradius.com on January 13, 2021

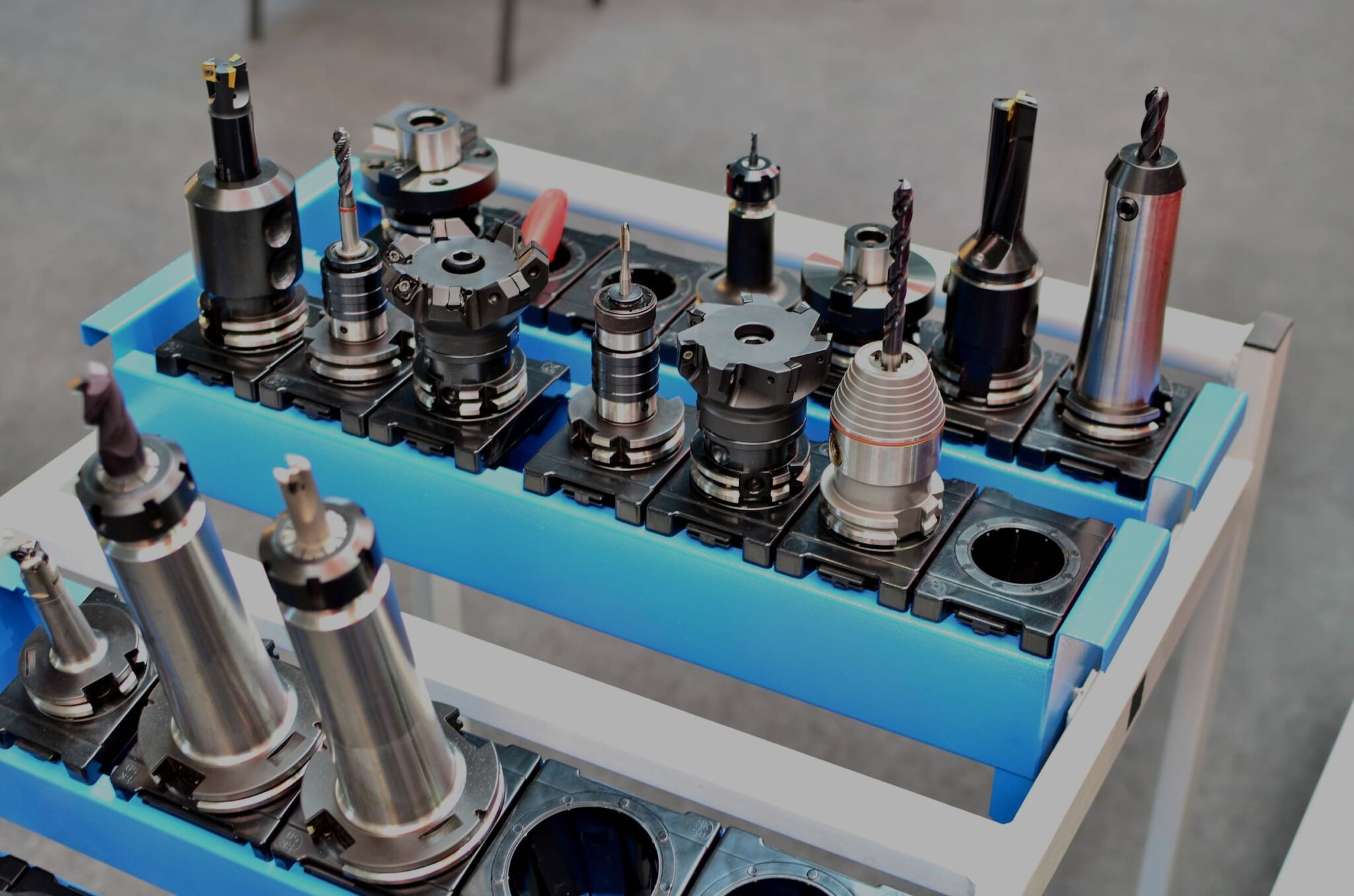

A fixture is a workholding device, or a tool that holds a part in place while it’s being CNC machined. When the part is simple, workholding is also simple; sometimes, the part can even be held in the machinist’s hand. But when a part is very large or has detailed features on more than one side, it demands more creative solutions.

Universal soft jaws and vacuum tables are two such solutions, but with an especially delicate or complex part, a custom fixture may be necessary. Of course, CNC machining a custom fixture means machining a part just to hold another part; for this reason, it’s generally not recommended except for high volume production runs. While creating a custom fixture requires a significant upfront investment in time and capital, it is likely to generate high ROI if used tens or hundreds of times.

However, as with machining parts with complex geometries, there are key considerations and best practices that can streamline and simplify the process of manufacturing complex fixtures.

Parts with complex shapes often demand fixtures with equally complex shapes — but a complex fixture can be almost as difficult to manufacture as the part it’s meant to hold. With fixtures that have complex locating features, machinists may be limited in the ways they can reach and hold the fixture; ideally, this problem should be mitigated by designing the fixture with the machining process in mind.

These key considerations should guide the design and manufacturing process for CNC-machined fixtures:

Although it can be expensive and time-intensive to create complex fixtures via CNC machining, there are certain advantages to using this manufacturing method. One of the most notable advantages is the ability to machine parts with particularly tight tolerances. CNC machining, which is extremely precise and replicable, can help ensure that there won’t be variability from one fixture to the next.

Another advantage of CNC machining is its ubiquity. As one of the most popular and commonly-used manufacturing methods today, there are countless machine shops in the U.S. and beyond, meaning product teams are unlikely to have a difficult time outsourcing projects to experienced machinists to assist in developing a given fixture.

Finally, the flexibility of CNC machining is worth noting. Unlike other manufacturing methods, CNC machining can be performed with a seemingly endless range of materials, from metals and plastics to wood and foam. Other popular manufacturing methods, such as injection molding and 3D printing, are best-suited to manufacturing solely plastic parts.

Despite the many benefits of CNC machining, it’s not always the best option for a given fixture — but determining when it is or isn’t the best choice can be difficult. As a general rule, if a fixture consists of many separate, relatively small parts, additive manufacturing may be a better choice than CNC machining.

However, that’s not a hard and fast rule, and identifying individual cases in which additive can help product teams save time and money while creating their complex fixtures can be tricky. That’s why partnering with an experienced design and manufacturing consultancy like SyBridge can help.

SyBridge’s team of expert designers, engineers, and manufacturers come to the table with deep technical knowledge of a range of manufacturing methods, design principles, material selection, rapid prototyping, production, and fulfillment. We don’t specialize in a single process — we’ve mastered the entire product development lifecycle. We’re prepared to help any product team identify and leverage best-fit materials and methods to ensure that desired results are always achieved — at a competitive price point and on a rapid timeline. Contact us today to get started.

How SyBridge Expertise Optimizes Your Process and Lowers Costs In the fast-paced world of manufacturing,…

Imagine a world where your product stands out on crowded shelves, not just visually, but…

Injection molding is an efficient production method when high volumes of identical parts are needed. However,…

As a production method, urethane casting sits in stark contrast to the hard tooling of injection molding. Whereas injection…

CNC machining is among the most popular manufacturing methods because the process is highly versatile, repeatable,…

Originally published on fastradius.com on October 20, 2021 Multi Jet Fusion enables the efficient production…