Originally published on fastradius.com on December 22, 2020

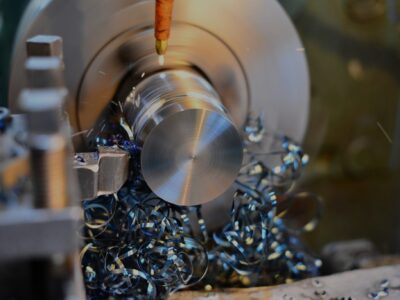

CNC machining is a traditional manufacturing method that utilizes cutting tools and rotation to make a predetermined series of cuts to a solid block of material. The cutting operations are derived from digital design files, which can be distributed to multiple CNC machines simultaneously, enabling manufacturers to produce multiple copies of a part more expeditiously.

While machining is a versatile process capable of reliably producing highly precise and accurate parts — why it’s often used to create critical automotive, medical, and aerospace components — the inherent nature of the process creates limitations to the geometry that’s possible to create with CNC machining. Design elements like sharp internal corners, for instance, are difficult to create with round, rotating tools, while undercut features like dovetails and T-slots are hard, if not impossible, to reach with standard tools.

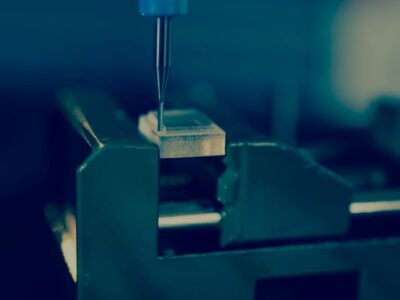

Another potential issue has to do with workholding, or how the workpiece is fixed in place during the machining process. If workpieces are hard to grasp or are grasped improperly, the part’s viability, production timeline, and per-unit cost may all be negatively impacted.

Here’s what manufacturers need to know about getting the most from their workholding solutions.

The basics of CNC workholding

How a part is held can significantly affect a number of logistical factors, including viable toolpaths, which workpiece surfaces will be machinable without additional setups, and the allowable speed and force of the cutting tools. Basic workholding components like jaws, vises, and even the machine table can limit the ability of cutting tools to access the workpiece, which can lead to more time spent setting up the part, instead of running the spindle.

However, much like how 5-axis CNC machining provides cutting tools and workpieces with additional rotational capabilities during production, 5-axis workholding solutions can dramatically improve the efficiency of manufacturing parts that require machining on most or all sides.

Used in tandem, multi-axis machining and workholding solutions allow workpieces to be placed in an optimal position, gripped once, machined, then quickly changed out. This is often achieved via zero-point, quick-change systems, which ensure reliable workpiece placement while allowing components to be efficiently transferred to other machines for secondary operations as needed.

When implemented properly, CNC workholding systems can improve output efficiency by minimizing the time required to set up and change workpieces. Workholding solutions assist in making production processes repeatable, which further contributes to measurable improvements in speed of production and process reliability, as well as the accuracy, precision, and quality of the final parts.

Common CNC workholding challenges

The most common CNC workholding challenges arise when manufacturers attempt to produce parts with unusual geometries or parts that are cumbersome and large.

Aside from optimizing part design for manufacturability (DFM), what’s the best way to keep unusual, delicate, or thin-walled workpieces stable and secure during machining? In many cases, sacrificial tooling is used to support workpieces with non-standard shapes, and built-in design features like dowel pin holes or threaded bosses can often be used to clamp the workpiece in place. Even incorporating as little as an additional 1/16” of material to the bottom of a workpiece can increase its ability to be gripped.

Sometimes, manufacturers may need to adopt more creative solutions, however. Sandbags, for instance, can be used to reduce workpiece vibration, while waxes, clays, and speciality glues can help support delicate sections of the workpiece. Waxes and clays, in particular, are fairly rigid at room temperature and become fluid when exposed to higher temperatures, which is helpful when removing them after the machining process is complete.

Bulky parts — such as those used in aerospace, defense, industrial, or vehicular applications — present another challenge. Speciality and custom workholding options are expensive and, considering some large components are only produced in relatively limited volumes, may not be worth the investment. If used for large production runs or repurposed for use with other parts, however, a custom workholding solution may offer a good return on investment.

Whether a shop chooses to invest in specialized or automated workholding solutions for larger parts or uses a combination of manual chucks, jaws, and other off-the-shelf solutions to keep the workpiece stable, the goal should be to minimize the total number of cutting operations and repositionings so as to maximize spindle run time. Limiting the number of cutting operations also minimizes the opportunity for human error, improves process reliability, and typically improves machining accuracy.

In addition to size, the shape of cumbersome parts should be taken into consideration. Inherently asymmetrical components, like turbine blades, require complex, sweeping spindle and tool motions. These types of challenging parts require workholding solutions that can rigidly hold a part in the proper position, while also allowing for clearances required by the cutting tool and machine.

Choosing the best workholding solution

The workholding solution best-suited for a particular part will be determined by a few factors, including production volume, part shape, part dimensions, material, and tolerance requirements, as well as changeover frequency.

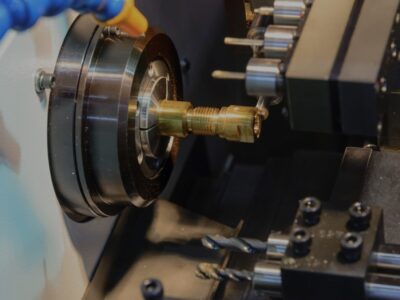

High-volume machining has different foundational requirements than smaller jobs: it depends on reliably repeatable processes that produce parts of consistent quality over extended timelines, which typically requires specialized workholding solutions. Dead-length chucks are a common solution, as they’re capable of providing both high positioning accuracy for secondary machining operations and increased gripping force, which is useful for securing castings or forgings during roughing operations.

In contrast, low-volume CNC machining jobs can typically rely on traditional workholding tools. Collet chucks, which employ sliding sleeves, can effectively grip round, hexagonal, and square workpieces and bar stock without losing holding power — a significant concern when working with rotation and centrifugal force. Three-jaw chucks are also commonly employed, as they provide superior grip when machining round workpieces, while two-jaw chucks (or 2+2 four-jaw chucks) are excellent for working square parts.

However, these traditional workholding solutions often introduce additional considerations. Clamps increase the number of steps involved per operation and can interfere with multi-axis machines’ access to the workpiece, while vises place constraints on the size and type of workpiece that can be gripped.

Workholding is key to production efficiency

Manufacturers rely on CNC machining to produce precise, repeatable parts. However, this precision is only possible if workpieces are held in a defined location with a known orientation. What’s more, the repeatability of CNC machining requires that the machining setup can be economically reproduced over the course of production. Therefore, in addition to securing the workpiece against centrifugal force, gravity, and tool-cutting forces, the most effective and strategic workholding solutions should help to lower labor costs while minimizing tool and setup changes.

Modular workholding solutions that enable quick changes between workpieces and cutting tools without interrupting production, the integration of Industry 4.0 technologies, and improved automation are some of the technological developments poised to streamline the world of CNC machining. These features will likely help manufacturers achieve more with less labor, by providing greater production flexibility and capacity, as well as improved consistency in changeovers between parts and distinct jobs.

However, CNC machines are hefty investments, which is why it is often more cost-effective to outsource CNC machining to a trusted manufacturing partner than to bring machining services in-house.

The good news is that Fast Radius is part of the vanguard of on-demand CNC machining. Our team of seasoned engineers, designers, technologists, and operators have decades worth of experience in streamlining the CNC machining process while saving customers time and money. We work closely with customers through every stage of production, helping to select the ideal production method and workholding solutions for every job, and deliver high quality products at a competitive price point. Contact us today to get started.