Originally published on fastradius.com on March 15, 2021

Despite the advancements of the digital era and updated enterprise software, many manufacturing companies still support outdated design and production systems to ensure they are able to create parts they have made in the past. However, this arrangement can actually be a liability.

As the software and tools used to develop the schematics for these parts have advanced beyond the capabilities of the original software — or as engineers and designers responsible for the original designs retire or change jobs — manufacturers run the risk of losing valuable design data and operational efficiencies.

However, given the operational speed and efficiency of additive manufacturing technology, you might find that, in some cases, it’s far more efficient and economical to 3D print your legacy parts rather than reproduce them with original methods. Creating computer-aided design (CAD) files of legacy auto parts, legacy heater parts, legacy pool parts, and more can actually prevent those designs from being lost entirely.

Furthermore, if a product needs to be updated, it’s obviously far less efficient and cost effective to have to create a design from scratch. Transferring legacy part drawings to CAD files can streamline the process of documenting and implementing any future updates.

Here are the three primary methods for creating CAD files for the purpose of 3D printing legacy parts:

Drawing conversions

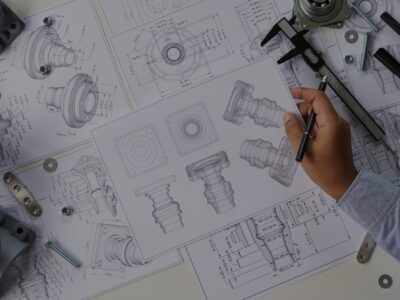

This is as straightforward as it gets. When you have the 2D technical drawings for a part, the simplest solution is to create a CAD file directly from the illustration’s specs.

Reverse engineering

In cases when technical drawings aren’t available, the next-best option is to reverse engineer the legacy part. The reverse engineering process begins with creating a technical drawing of the piece, which you can then use to generate a three-dimensional CAD file. This requires an intact copy of the part that can be measured, and subsequently recreated as a CAD file with all the right specifications for the component’s performance properties and tolerances.

Reverse engineering builds off existing knowledge rather than starting from scratch, using the surface dimensions of an existing legacy part as a reference point for the updated, digital design. The process can illuminate the logic behind the original part’s design — a concept known as design intent — which, when properly leveraged, can help lower development costs and shorten production timelines.

Reverse engineering is an ideal solution for updating the design of existing parts, developing pieces to fit with existing parts (such as housings for electronics), repairing worn or broken legacy parts, and for creating CAD files when no technical or dimensional drawings exist. In most instances, this process is more efficient than 3D scanning for creating files for smaller components like brackets, enclosures, gears, and other mechanical pieces

High-resolution 3D scanning

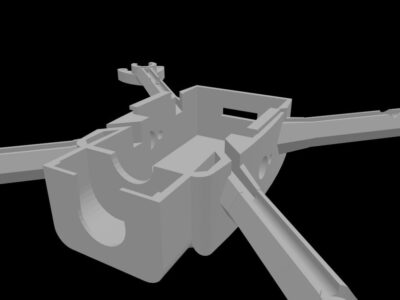

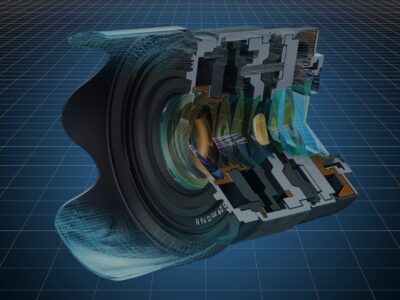

The last resort is to use a high-resolution 3D scanner, which generates a detailed, accurate 3D polygon mesh or point cloud of a physical object.

In many instances, the mesh can be printed as is or serve as a guide for reverse engineering via direct overlay, but in some cases it will require further optimization before the design can be additively manufactured. Optimization can include everything from closing gaps in the mesh or incorporating cavities that the scanner may not have detected to fully reverse engineering the scan data into one or more CAD file formats. Factors like part geometry, material, and application can impact the extent of optimization required.

High-resolution 3D scanning is well-suited for converting legacy parts that require exact replicas or precise fits, or those that would present too much of a challenge to reverse engineer manually, such as those with complex surface geometry that is not easily measurable.

Create CAD files for 3D printing the easy way

Components such as legacy auto parts, and other outdated or niche products are often incredibly useful for you to have on hand. However, many of these products still require access to otherwise obsolete manufacturing methods, which are becoming more of a liability in an age defined by ever-increasing efficiency. By using 3D scanning technology and reverse engineering, you’ll be able to update your technical drawings for legacy parts to state-of-the-art CAD files — cutting costs and simplifying your operational processes as a result.

Of course, partnering with an on-demand manufacturer like SyBridge can take the challenge off your shoulders entirely. Our team of seasoned engineers and designers bring decades of expertise to bear with each job, which allows us to rethink what’s possible in modern production. We’ve developed innovative multi-process manufacturing methods that deliver the superior quality you’d expect — on far shorter timelines and at competitive prices. Contact us today to learn more about why we’re the partner best-suited to help convert your legacy parts to 3D-printable CAD design files.