by Charlie Wood, Ph.D.

VP of Innovation, Research & Development

As a part of the SyBridge team, I’ve witnessed the remarkable evolution of design and engineering tools over the past decade. These digital advancements have revolutionized our approach to manufacturing, allowing for more data-driven processes and insights. But it can be difficult to know where to start, or even to understand where there are opportunities to implement.

At the heart of our approach lies the concept of the “Digital Thread,” a framework that interconnects data across the entire lifecycle. This concept enables us to leverage the wealth of design and operational data across our data lake that is generated in the manufacturing process, from CAD designs to inspection results. While the industry is still moving towards seamless integration, we’ve made significant strides in creating workflows that prioritize data-driven decision-making.

Streamlining Injection Mold Design Workflows

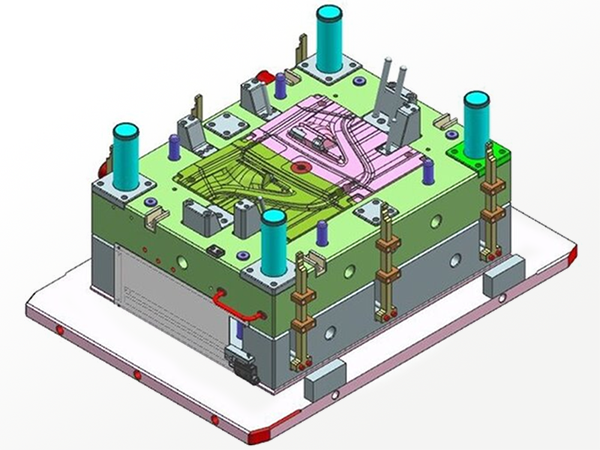

One key area where data is contributing to efficiencies within manufacturing is that of injection mold tooling design. By utilizing virtual component libraries for mold designs, we’ve been able to streamline the complex process of coordinating and collaborating on intricate assemblies for mold making. In these libraries, we have standard blocks, system approaches and components stored in a way that allows us to quickly identify and digitally pull components. This approach offers lots of flexibility when it comes to customer requests and needs, all while keeping standard practices built right into our tools. Over the course of many years, we’ve built software-driven processes to design new builds based off of these standard components, allowing us to quickly handle new requests from customers and build a learning feedback loop to avoid costly mistakes.

Additionally, through the use of parametric component libraries, we’ve been able to significantly reduce design complexity and incorporate our own manufacturing intelligence into these components, allowing us to directly check for design issues and integrate manufacturing information into CAD files. This process creates a flow of information from the conceptual stage of the design through manufacturing and approval, extending our Digital Thread from end to end. This information flow can also go backwards, tying quoting, estimation assumptions and specifications directly to tool designs. These advancements in our design approach have not only made the job of a tool designer a bit easier, but have improved quality by creating

more explicit feedback loops in our design processes.

Innovations in Conformal Cooling

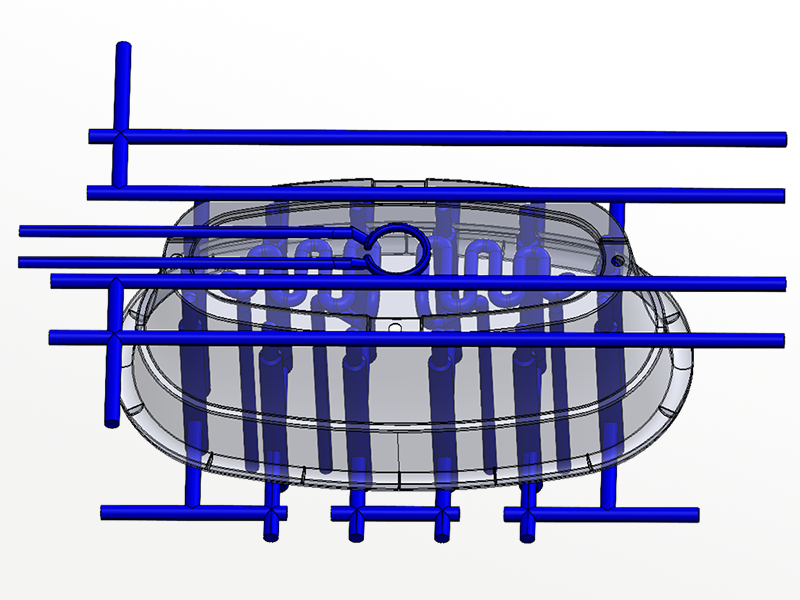

As many know, 3D printing has unlocked incredible design freedom for manufacturing engineers around the world. However, what can be overlooked is how impactful it has been for system designers, like toolmakers, who can utilize that design freedom and low cost of complexity to create components that radically improve performance. In the case of toolmaking, 3D printing has unlocked new cooling channel designs simply not possible before.

Although increasing numbers of toolmakers are using these advanced manufacturing techniques today, the new design space is so complex it can be hard to probe. In the past, conformal cooling channels were fairly straight, in-plane paths driven by tool access limitations in machining. With metal 3D printing, the limits are far less restrictive and allow designers to pursue more creative and complicated structures.

Using advanced data-driven methods with virtual design and testing capabilities, we’ve been able to uncover non-obvious opportunity areas in the design space. Through these novel design and

manufacturing workflows, we’re optimizing cooling performance and achieving remarkable improvements in tool performance as measured through cycle time. Through our approach, we’re seeing cycle time reductions as high as 50%. These successes have inspired us to further integrate and enhance these workflows, driving continued innovation.

AI Tools for Manufacturing

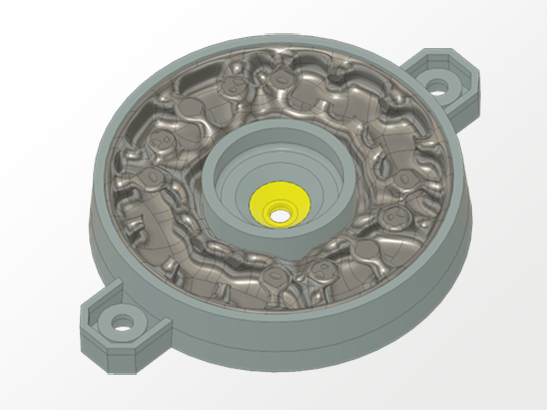

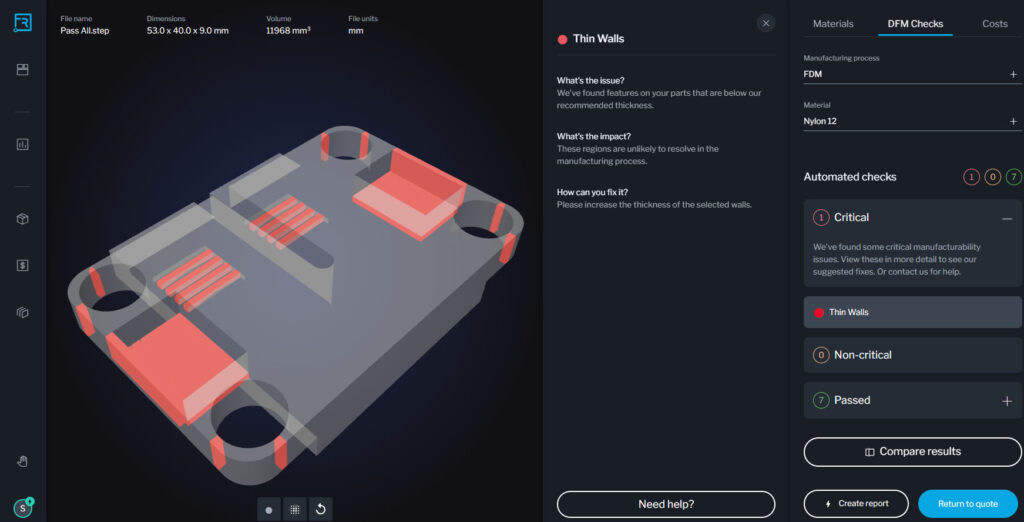

The Fast Radius Portal’s AI-powered DFM checks

Looking ahead, we’re enthusiastic about the possibilities that emerging technologies like machine learning (ML) and artificial intelligence (AI) offer. These novel data modeling approaches have shown incredible potential, and the pace of technological advancement is rapidly accelerating. We’ve been able to use ML models to build data models faster than through simple bottom-up logic, particularly for complex problems that contain many correlating factors.

The critical ingredient in implementing AI for manufacturing are large data sets that provide a source of truth for model training and validation. By leveraging our existing datasets, we aim to predict defects, optimize designs in real-time and ultimately revolutionize quality control processes. These technologies are not a distant vision; they’re an integral part of our current digital platform, with features like instant quoting and DFM checks based on captured manufacturing data. And this is just the beginning of what’s possible.

Unlocking Manufacturing Innovation via the Digital Thread

Our journey in harnessing digital workflows for injection molding design has seen remarkable progress and tangible results. The end-to-end integration of data into the Digital Thread, combined with the power of ML and AI, holds the key to unlocking even greater innovation. As we continue to push boundaries and explore new frontiers, we’re excited about the advancements at the interface between the physical and digital worlds.

Are you ready to harness the power of the Digital Thread for your organization? Contact us today to get started.