Originally published on fastradius.com on February 22, 2019

A new suite of tools is creating a transformational impact on how to bring new products to the world. Manufacturing companies at the vanguard of Industry 4.0 aren’t just making revolutionary products and getting to market faster. They’re also creating less impact on the environment and moving away from old, carbon-intense manufacturing processes.

Take Husqvarna Group. When the company brought its 300-year legacy of producing outdoor power products to SyBridge, it sought to identify parts that could be made more efficiently and sustainably through additive manufacturing. This was a bold move for an established industry leader, but the Swedish company was determined to innovate on the way things have always been done. The success of this exploratory project has created a valuable opportunity for the company to take a stand about reducing its carbon footprint — important to its Sustainovate sustainability program, established in 2016.

It’s a good time to pause and take stock of the manufacturing industry today, and how additive manufacturing is poised to alter its relationship to environmental sustainability.

The manufacturing trends driving companies to digital manufacturing

To understand why additive manufacturing is such a pivotal technology at this moment in time, you first have to grasp the key forces at play globally within the manufacturing industry.

With 1 billion new people arriving in the consuming classes over the next decade, an additional $30T of demand in consumption and much of that growth within dispersed emerging economies, we’ll see a shift in the center of gravity for global manufacturing. This will create a profound acceleration of demand and goods transport worldwide. We’ve also moved from an era of economic liberalization into one where some nations may play an active role in protectionist trends. The very nature of globalization is changing, which impacts the supply chain directly.

The combining effect of these forces means that our industry needs to find more creative and efficient ways to design, make and fulfill new products to meet demand responsibly. To do so in a way that’s smart and sustainable requires a new approach to the supply chain, and new technology to fulfill that approach.

The sustainability benefits of additive manufacturing

As a human race, we certainly face our share of challenges today. But we’re also in an unprecedented time in history, experiencing a wave of industrial and informational innovation thanks to technologies that didn’t exist just a few years ago. Industry 4.0 technologies like robotics, artificial intelligence and machine learning, autonomous mobility, virtual reality — all are starting to create a huge impact on mainstream lines of business.

Additive manufacturing certainly belongs on the list. Where once the idea of 3D printing was a futuristic anomaly, additive manufacturing is now a relevant alternative to traditional manufacturing processes for all kinds of companies, and it’s rendering supply chains to be vastly more Earth-friendly. We now have at our disposal tools that allow never-before-possible design outcomes and ways of meeting increased consumption.

In terms of sustainability, there are four benefits additive manufacturing typically brings:

1. More efficient product design

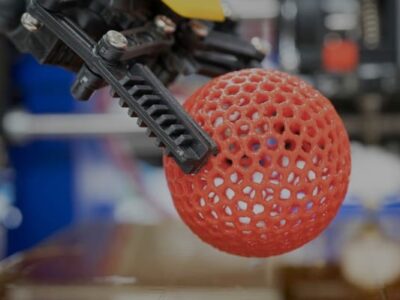

Inherently, additive manufacturing results in products designed to use less material. There are several examples of this. The first example is advanced digital tools of design that enable new design capabilities, like lattice structures, which create enormous strength with far less material. The second is that now, thanks to additive manufacturing, multiple parts can often be consolidated into one, which means less overall material is being used to manufacture that product.

2. More efficient manufacturing processes

Most traditional manufacturing techniques are subtractive, meaning that a block of material is cut to form or an injection mold is produced and filled. This results in scrap waste, some of which can be repurposed, some of which cannot. At any rate, even to recycle material, it must be reprocessed. The additive process, on the other hand, involves no molds and no waste carved away. There have also been great strides made in the ability to reuse surplus material. For example, HP High Reusability PA 12 has up to an 80 percent reuse rate on excess powder. As an industry, we have high hopes for continued sustainability innovations in the materials space.

3. More efficient supply chains

Traditionally, supply chains have existed using the three modalities of logistics: ground, air and sea. Additive manufacturing creates a fourth, vastly more efficient modality: the Cloud. In this instance, the Cloud is replacing physical storage with a Virtual Warehouse. The ability to print on demand, rather than having to produce large volumes of parts or products at once and then store them, plays a part in reducing obsolescence costs. In the near future, companies will upload part designs digitally and print them on demand in a global network, closest to the point of consumption, which reduces reliance on carbon-heavy transportation methods. Because additive manufacturing facilities will be replicated worldwide, it’s possible to envision a world where the integration of digital and physical logistics defines the future supply chain.

4. Accelerated innovation and time to market

Finally, because additive manufacturing allows for rapid iteration of ideas without the prototyping limitations of traditional manufacturing methods, companies are empowered to get products to market faster, responding to human need more quickly, with a far more efficient use of materials, processes and people.

Looking to the future of Earth-friendly manufacturing

With these Industry 4.0 innovations within our reach, we can soon meet the challenge of creating a better, more efficient, more environmentally responsible industry for future generations. A handful of progressive Fortune 100 companies are already leading the charge, converting parts of their supply chain to additive manufacturing in order to create better performing products, cut down on their carbon impact, and become more nimble overall.

There is still much work to be done to meet today’s environmental and global challenges, but the promise and potential exists. If more leaders and engineers get together to learn and understand the new tools, and bring them into business in a meaningful way, we have an opportunity to create a step change in efficiency across the manufacturing economy. Contact us today to get started.