Originally published on fastradius.com on July 1, 2020

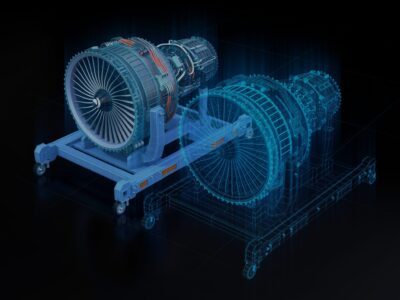

Digital twin technology is software solution that uses sensors, cameras, and other forms of IoT data collection to create a virtual model of a process or product that not only interactively updates with its physical counterpart, but can also be used to test how the part or process responds in different scenarios. Used properly, digital twin technology can help companies optimize their products and processes to be more efficient and cost-effective.

The concept is still relatively young, but digital twins have already demonstrated profound practical applications. The supply chain management sector, for instance, uses them to model warehouse layouts and conditions before implementing changes — which research from McKinsey shows can improve warehouse efficiency by up to 25%. There are a couple applications that are especially relevant to manufacturers: processing and manufacturing, and predictive maintenance. Here’s how they work.

Digital twins: Data-driven virtual models

The first relevant application for digital twins in manufacturing uses the technology to create virtual copies of a part as the part is being created and post-processed. If engineers understand the manufacturing process thoroughly enough, they can model how the part properties will change during each process and phase of production before parts are ever made.

Digital twins also enable virtual field-testing through real-time conditions for products, which is especially useful for parts and components that are constantly being exposed to different conditions for long periods of time. These pieces may fail after six months or after several years depending upon conditions, but inputting measurements for temperature, humidity, run time, and various operating conditions (such as whether it’s part of a motor system) into a digital twin can give manufacturers a clearer picture of how the product is performing in real time, as well as what its lifetime is.

A digital twin can help predict when a given part has a high probability of failure, so it can be serviced preemptively to avoid any interruption to operations. As it stands, it can be difficult to gauge relative wear or predict the service life of a part with accuracy, which can lead to costly part failures or unnecessarily early part replacement. The right time to service components will of course depend on a number of factors — including application, durability, wear, and environment — but digital twin technology can help extend the effective lifetime, and value, of a part through data-driven strategic servicing.

The primary disadvantage of digital twin technology is that it requires good data and models to be useful. The technology infrastructure needed to build out a digital twin that collects the right data, consolidates different data sources, and analyzes the data correctly can be more complicated than designing the part itself.

The data sources that are most relevant will vary by part application, but in general, the environmental and operating conditions of the part (such as temperature, humidity, speed of operation, etc.) are vital. The part’s material information is as important as its geometry, and that information needs to be overlapped as well.

The future of digital twin technology

Digital twin technology utilizes large data sets to provide greater visibility into the state of various parts, helping companies to pinpoint critical infrastructural needs and practice predictive maintenance. It should come as no surprise, then, that companies across market sectors have been quick to take advantage of the benefits afforded by digital twins. In fact, Gartner predicts that half of all industrial companies will use the technology in some capacity by 2021, and additional research predicts that not only will almost 90% of IoT platforms support digital twinning by 2025, but that it will become a standard feature for IoT apps by 2025. The technology has a wide range of potential applications and uses, many of which are still untapped.

In order to gain actionable insights into products or processes that digital twins provide, manufacturers and product teams will need to either find a software partner to help collect and analyze the data, or develop those capabilities internally. Data collection is important, but it’s a far cry from a comprehensive solution: garnering valuable insights requires both a wide variety of data and the tools and skill sets needed to analyze it properly. If the digital twin of a complex system is collecting data from five or six different sources, for example, centralizing that data into one place can require specialized software solutions to ensure an integrated way to probe and analyze the data.

SyBridge is a dedicated team of engineers, designers, strategists, and technologists determined to do manufacturing differently. We understand the cutting-edge of manufacturing, because we’re defining it. We collaborate with each of our customers to guide parts from design through to post-processing, on time and without issue. Want to tap into the revolutionary power of digital twins? Contact us today to get started.