Originally published on fastradius.com on June 10, 2020

One of the most popular methods for plastic parts manufacturing, injection molding is favored for its ability to facilitate large production runs of identical parts. The injection molding process isn’t overly complicated — in its simplest form, it requires only two steps: obtaining the mold, and using the mold to create parts. What’s more, in almost every case injection molding is the least expensive way to produce parts in medium to high volumes.

Once the initial mold has been made, the price-per-unit cost is comparatively low. In addition, because injection molding creates identical, perfectly molded products every time, it significantly cuts down on waste material compared to other manufacturing processes like CNC machining. For these reasons, plastic injection molding is a rapidly growing industry. Valued at $258.2 billion in 2019, it’s predicted to reach a valuation of $372.9 billion in less than a decade.

That said, plastic injection molding does require a high level of precision. Here are the steps manufacturers must follow to create parts using injection molding.

A Note Regarding the Tooling Process

Despite the clear advantages of injection molding, the process is not without drawbacks. Namely, the upfront tooling costs and significant lead time required are obstacles for many manufacturers. While tooling might be considered the first phase of the injection molding process, for our purposes we’re considering it separately because it’s a heavily-involved undertaking that need only be completed once for each product.

Tooling requires product design teams to design and prototype a part — often via 3D printing — and then to create a mold that can be used to reliably make the part. This requires extensive testing and optimizing, but once the mold is complete, the same injection molding process can be completed thousands of times to create identical parts.

The Injection Molding Process Steps

Assuming that the mold has already been created, injection molding becomes an easily-repeatable process consisting of six discrete steps:

1. Clamping

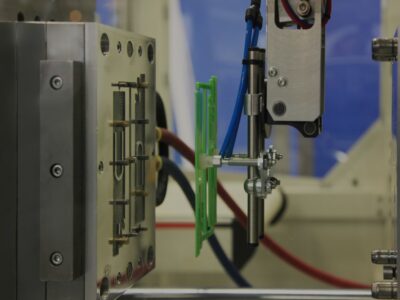

The first step of the injection molding process is clamping. Injection molds are typically made in two, clamshell-style pieces. In the clamping phase, the two metal plates of the mold are pushed up against each other in a machine press..

2. Injection

When the two plates of the mold are clamped together, injection can begin. The plastic, which is typically in the form of granules or pellets, is first melted down into a complete liquid. Then, that liquid is injected into the mold. Manufacturers should take care to ensure the temperature remains constant throughout this step of the process

3. Dwelling

In the dwelling phase, the melted plastic fills the entirety of the mold. Pressure is applied directly to the mold to ensure the liquid fills every cavity and the product comes out identical to the mold.

4. Cooling

The cooling stage is the most straightforward; the mold should be left alone so that the hot plastic inside can cool and solidify into a usable product that can be safely removed from the mold.

5. Mold Opening

Once the part has cooled, a clamping motor will slowly open the two parts of the mold to make for a safe and simple removal of the final product.

6. Ejection

With the mold open, an ejector bar will slowly push the solidified product out of the open mold cavity. The fabricator should then use cutters to eliminate any waste material and perfect the final product for customer use. Waste material can often be recycled and reinjected for the next part, decreasing your material costs.

A Partner in Injection Molding

Given the time and cost of tooling, injection molding can be an intimidating prospect. But, once the first mold is created, injection molding is the easiest way to create countless identical parts at a low cost — which is why it’s one of the fastest-growing practices in manufacturing today.

If you’re interested in getting started with injection molding, SyBridge is here to help. We’re experts when it comes to expediting the process of creating a perfect mold, and we provide every customer with unparalleled support during every phase of the production lifecycle. Contact us today if you’re ready to get started.