CNC machining is among the most popular manufacturing methods because the process is highly versatile, repeatable, and reliable — plus, it is compatible with a broad range of materials, from wood and plastic to foam and metal. Product teams that focus on DFM throughout the design phase can drastically reduce production times and costs associated with CNC machined parts.

In this downloadable guide, we’ve compiled eight common DFM considerations that should remain top-of-mind when designing parts for CNC machining. You can save significant time and cost by checking your design against this list before submitting it for manufacturing.

Top 8 Design for Manufacturing Considerations for CNC Machining

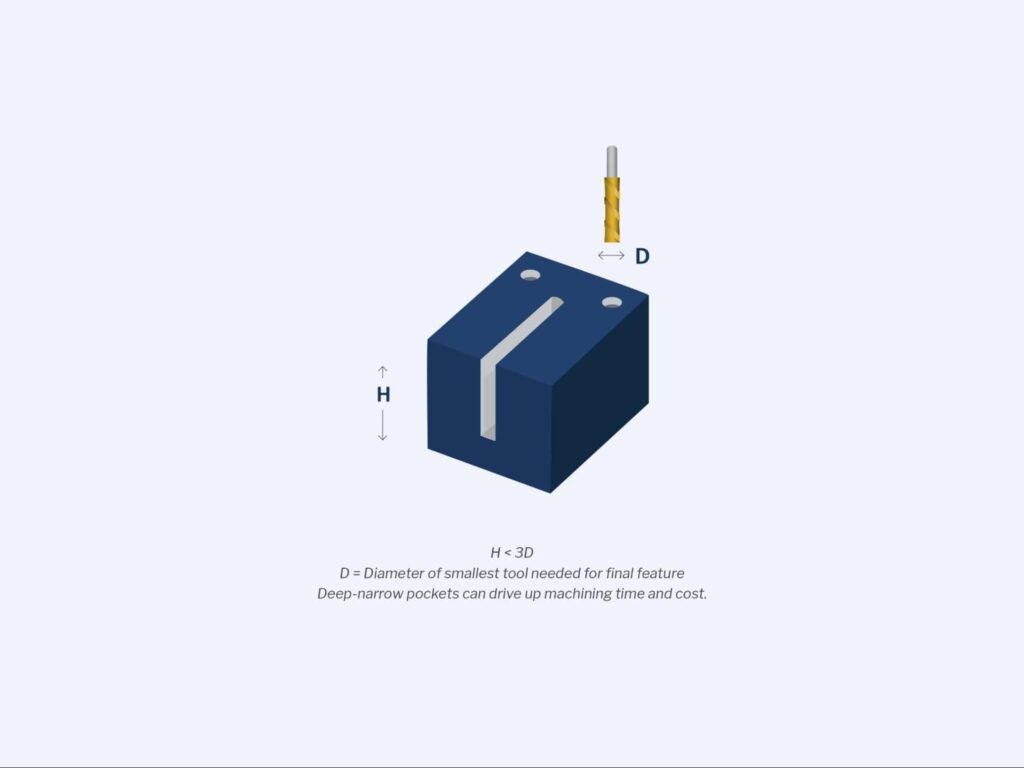

1. Are there any deep pockets in the design?

Deep-narrow pockets or slots must be machined by longer tools, and longer tools are more prone to breakage, and can also cause chatter, or machine vibrations. Additionally, it takes several passes to machine a deep pocket, which drives up machining time and manufacturing costs.

Avoid designing parts with deep pockets whenever possible. If a deep pocket cannot be avoided, engineers and designers should decrease its depth as much as possible or increase the cross-section area of the pocket. As a rule, pocket depth shouldn’t exceed 3x the diameter of the tool being used to make it. For example, pockets should be no deeper than 1.5” when using a 0.5” cutter. Engineers may have to adjust this figure based on the material they are using and the tools that are available to them.

2. Are there any narrow regions?

Narrow regions are difficult to manufacture because the size of the cutter is restricted by the smallest distance between the various faces of the feature. Long and small diameter cutters are prone to breakage and chatter.

Avoid designing features or faces that are too narrow for a cutter to easily pass through. If narrow regions cannot be avoided, however, they must not be too deep. Remember that the depth of any feature should be less than 3x the diameter of the tool. As a best practice, wall sections should be greater than 0.01 inches thick. A shorter cutter with a larger diameter can also be employed to reduce chatter.

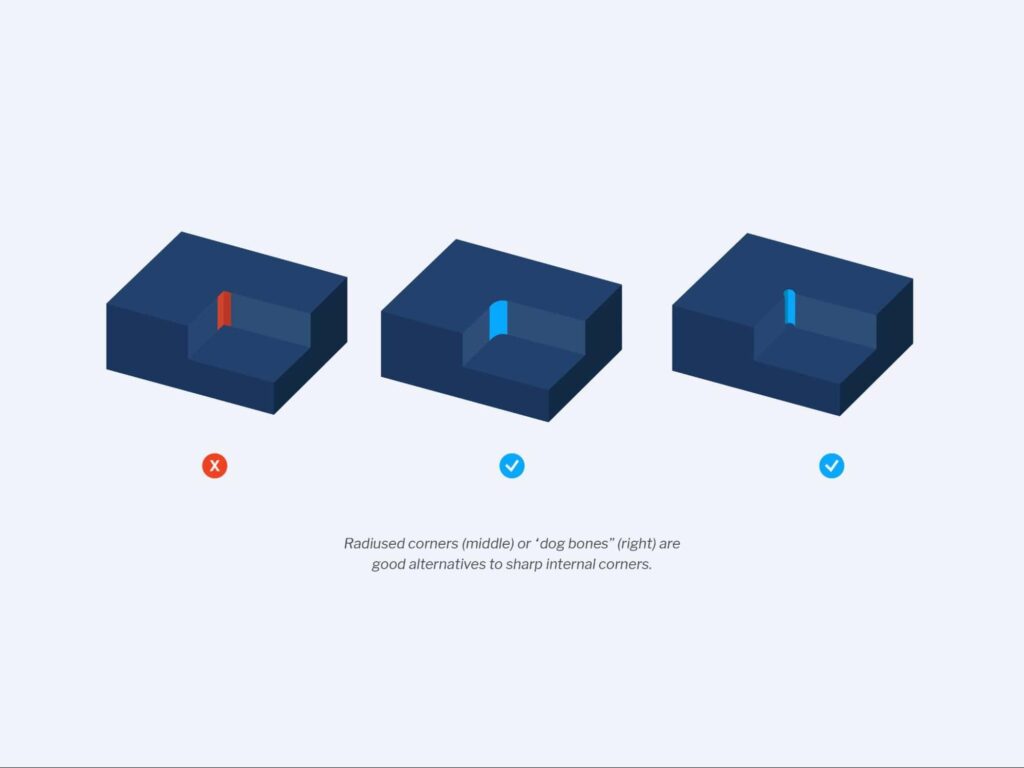

3. Are there any sharp internal corners?

Since all CNC drill bits are circular, it’s difficult to achieve sharp internal corners. Instead, the drill bit will leave behind a pocket of unmachined space called an internal corner radius. It’s possible to machine sharp internal corners using workarounds, like electrical discharge machining, but these methods tend to be expensive.

Avoid sharp inside corners whenever possible. Ideally, a corner radius needs to be slightly larger than the cutter. If a corner radius is the same diameter as the cutter being used to form it, it can cause chatter and premature tool wear.

Increasing the corner radii beyond the standard value by as little as 0.005” can give the tool enough room to move around and follow a more circular path.

4. Are there any inaccessible features?

Inaccessible features like counterbores that open inside another pocket or pockets with negative drafts take longer to machine— if they’re even possible — because the cutting tool cannot easily access them, which in turn drives up costs.

You should ensure a cutting tool has full access to all features within a part without being blocked by another feature.

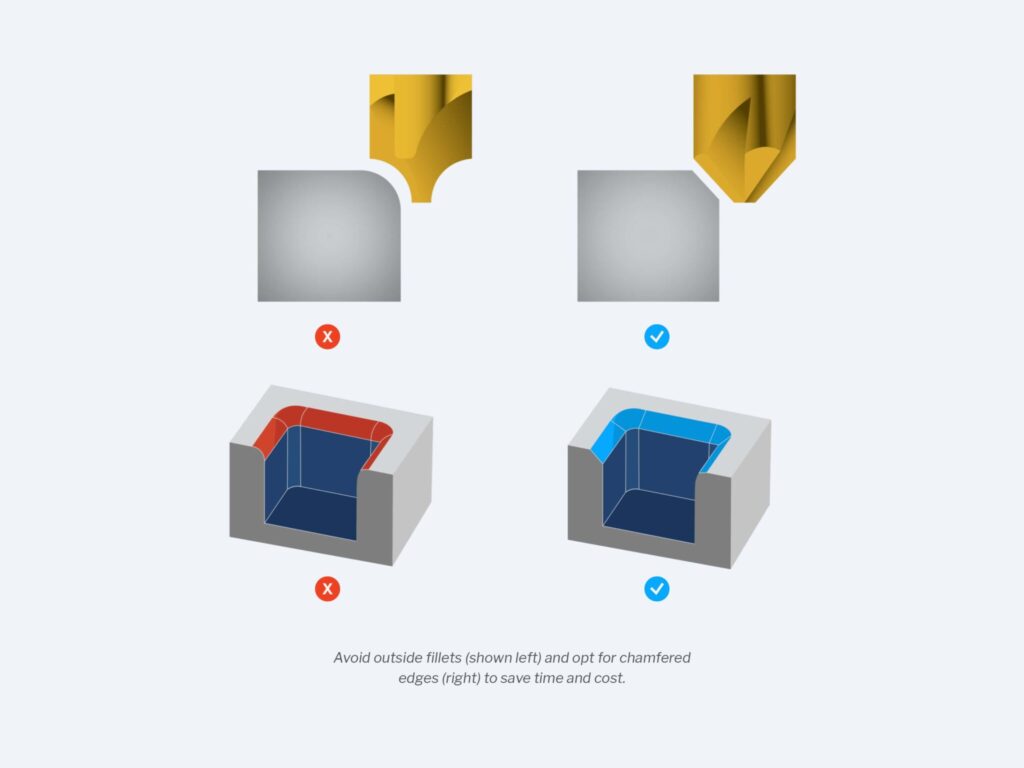

5. Are there any outside fillets?

Outside fillets, or fillets on the top edges of pockets, bosses, and slots, require an exceptionally sharp cutter and a precise setup. Both of these requirements can be prohibitively expensive for some product teams. To avoid incurring these costs, bevel or chamfer — rather than fillet — the outside edges of features.

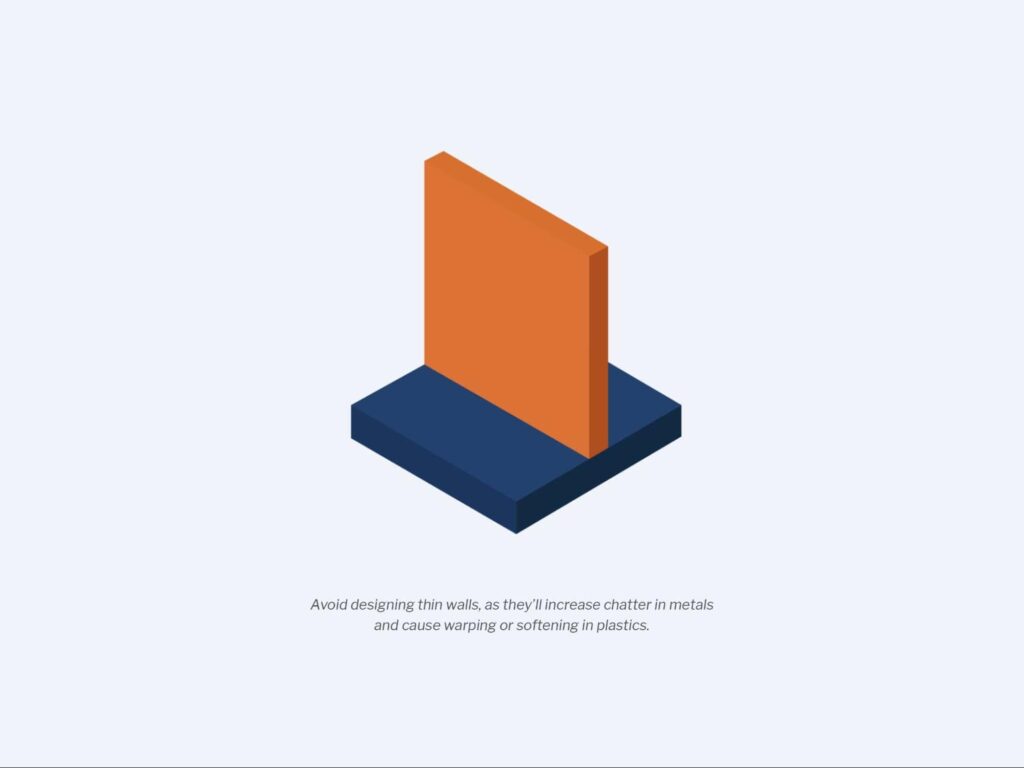

6. Are the part’s walls too thin?

When it comes to CNC machining with metal, thin walls increase chatter, which can compromise the accuracy of the machining process and the surface finish of the part. With plastics, thin walls can cause warping and softening. As such, you should do your best to avoid designing parts with thin walls.

The ideal minimum wall thickness for metals is 0.8 mm for metals and 1.5 mm for plastics. You may be able to achieve thinner sections without significant risk, but this needs to be assessed on a case by case basis.

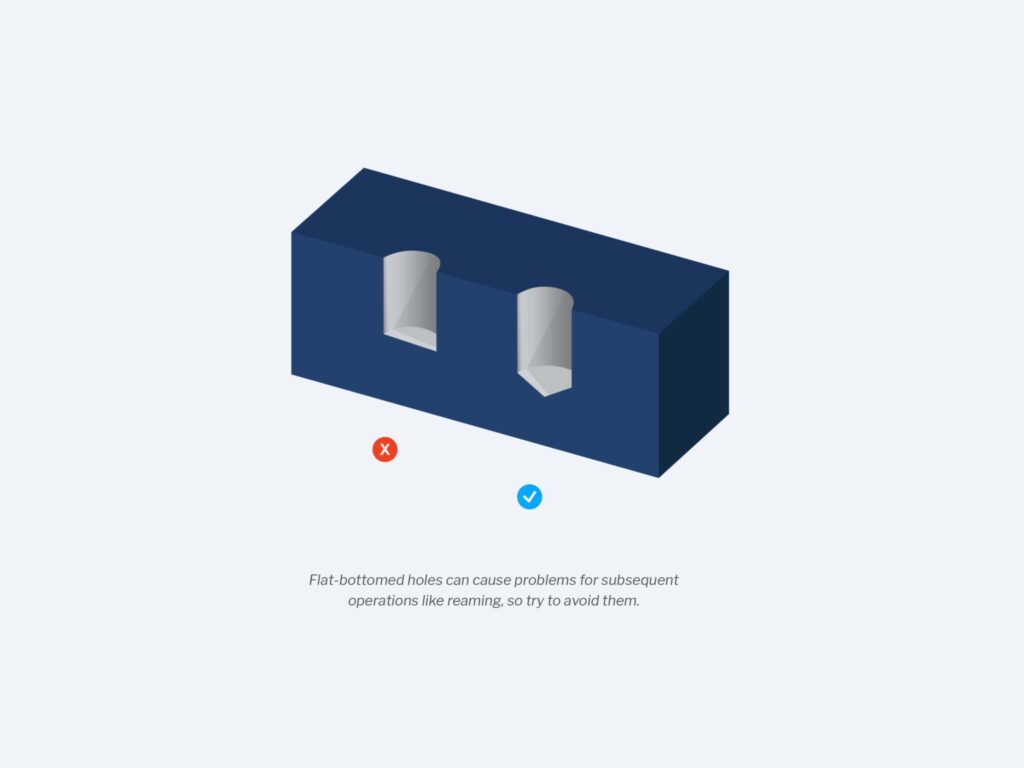

7. Are there any flat-bottomed holes?

Flat-bottomed holes require advanced machining operations and often cause problems down the line for subsequent operations like reaming. Avoid creating blind holes with a flat bottom — especially small holes — and instead use a standard twist drill to create holes with cone-shaped bottoms. Cone angles are commonly 118° or 135°.

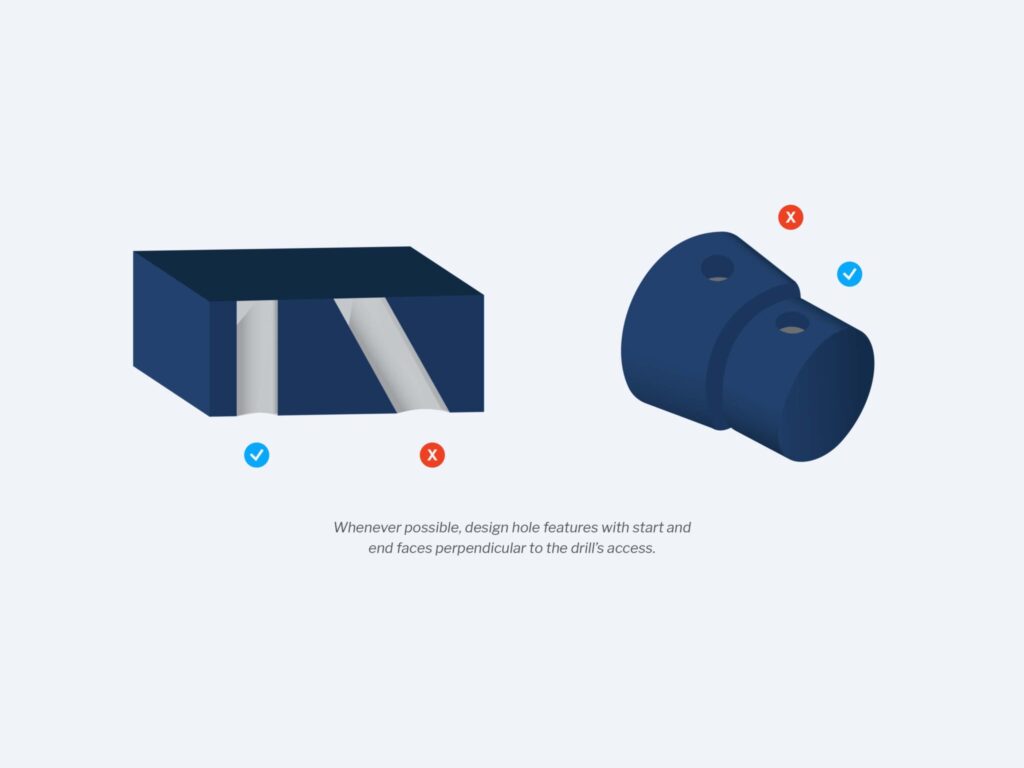

8. Can the CNC machine’s drills enter and exit easily?

A drill tip will wander when it comes into contact with the material’s surface if that surface isn’t perpendicular to the drill axis. Also, uneven exit burrs around the exit hole will make removing the burr difficult. To ease entry and exit, avoid designing hole features with start and end faces that are not perpendicular to the drill’s axis.

Recap of All 8 Design Considerations for CNC Machining

- Avoid designing parts with deep pockets whenever possible because deep-narrow pockets can drive up machining time and cost.

- Avoid designing features or faces that are too narrow for a cutter to easily pass through to prevent tool breakage and chatter.

- Radiused corners (middle) or “dog bones” (right) are good alternatives to sharp internal corners.

- Ensure a cutting tool has full access to all features within a part without being blocked by another feature

- Avoid outside fillets (shown left) and opt for chamfered edges (right) to save time and cost.

- Avoid designing thin walls, as they’ll increase chatter in metals and cause warping or softening in plastics.

- Avoid Flat-bottomed holes that can cause problems for subsequent operations like reaming.

- Whenever possible, design hole features with start and end faces perpendicular to the drill’s access.

Get Started With a DFM Expert

Designing for manufacturability accelerates the CNC machining process, reduces operating costs, elevates energy efficiency, and helps product teams create clean, functional parts. Refer to this short checklist often to make sure your designs are on the right track, but an experienced manufacturing partner like SyBridge can offer more nuanced insights.

The SyBridge team can help engineers, designers, and product teams ensure they don’t miss the mark when it comes to DFM. We have access to the latest digital design technologies available so our partners can take their designs to the next level, while we provide expert advice on manufacturability and part quality. What’s more, our experts are prepared to assist customers with design and prototyping for a range of manufacturing methods — from CNC machining and injection molding to urethane casting and 3D printing. Let’s create something incredible. Contact us today.