Originally published on fastradius.com on May 5, 2021

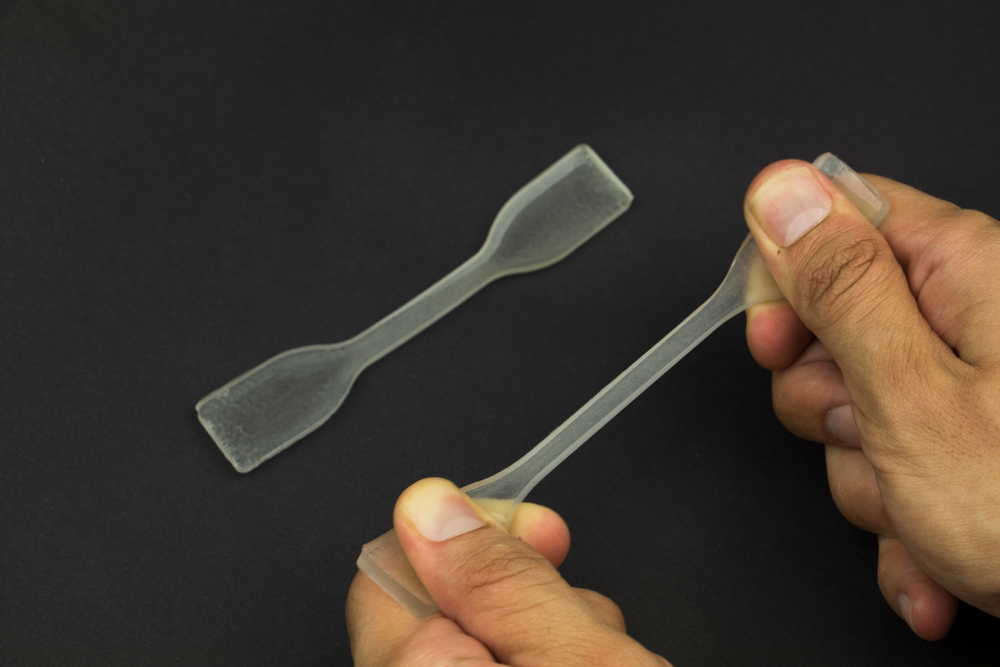

Urethane casting is a rapid and cost-effective method for producing end-use plastic parts in low to medium volumes. The process involves creating silicone casting molds from a part’s master pattern, then cutting the molds in half so that they can be brought to production. Able to support a wide range of viable part designs, urethane casting is commonly used for parts prototyping, bridge tooling, and fabricating parts with fine details, varying wall thicknesses, and complex geometries.

Among the process’ notable advantages, urethane casting can accelerate time-to-market, as most parts can be cast in less than two weeks. Further, casted parts tend to experience lower shrinkage rates than those produced through processes like injection molding.

Considering that urethane casting is a highly versatile manufacturing process, material selection can involve a variety of factors. It’s important that product teams do their due diligence to ensure they select the best-fit material for their given project.

Urethane Casting Material Selection Factors

Urethane casting is compatible with a wide range of both rigid and flexible materials — so cast urethane parts can be produced in a variety of colors, textures, and finishes. However, with so many options available, it’s important that you adhere to design for manufacturability (DFM) best practices when selecting a material. You’ll be weighing a complex set of factors, including:

- Application requirements: Does the part need to store or dissipate energy? Does it require tear resistance, load-bearing, or sound-dampening? Each of these factors necessitates different physical and chemical properties, which should help refine the pool of viable material options.

- Environmental considerations: If the application requirements will expose the part to extreme temperatures, humidity, UV radiation, or chemicals, these environmental considerations should also inform your material selection.

- Expectations: Other factors like cosmetic considerations and managing the customer’s expectations when it comes to part life, durability, and cost may play a significant role in determining the final choice.

Ultimately, determining the best-fit material for a given application is vital to ensuring the entire production cycle is positioned for success. Urethane casting materials including silicones, foams, and urethane casting resins can be categorized by their hardness according to durometer scale. Here’s a quick look at durometer, the Shore scale, and some of the most common urethane casting materials.

A Note on Durometer and the Shore Scale

Rubbers, plastics, and metals can vary widely in terms of their physical properties and characteristics, which has a direct impact on the applications for which each material is suited — a soft, bendable plastic obviously won’t do when hardened steel is required, and vice versa.

Durometer is the standardized metric for measuring the hardness of a given material, which is to say how resistant it is to local deformation. The durometer of most of these materials will fall into one of three categories: Shore 00, Shore A, or Shore D, each of which represent a range of hardness, with Shore 00 being the softest and Shore D being the hardest. Urethanes typically range in hardness from 25 shore 00 (something like a gel bicycle seat) to 75 shore D (something like a bowling ball).

Rigid Urethane (Shore D Resins)

The Shore D spectrum spans from rigid polyurethane resins to highly rigid ones. Most materials harder than 65 Shore D will feel completely rigid to the human hand and will not have the surface flex or bendability provided by softer Shore A materials. At the upper end of the Shore D spectrum comes the Rockwell scale, which is used to measure metals and extremely hard resins like acetals and nylons.

Common shore D materials include:

AFP3100 (85 shore D)

Extremely durable and resistant to both heat and impact, this rigid resin is often used to create covers and housings for consumer electronics and medical equipment. It is comparable to ABS and PC/ABS plastics.

AFP3200 (80 Shore D)

Similar to HDPE, this urethane offers high tensile and impact strength, rigidity, and stiffness, and is used extensively in consumer packaged goods, industrial piping and tanks, and auto body components like fenders, hoods, and wheel wells.

AFP3320 (80 Shore D)

This urethane is often used for high-heat applications due to its excellent heat and impact resistance. It is an excellent option for HVAC and underhood applications.

AFP3400 (70 Shore D)

Comparable in many ways to polypropylene, this material offers flexibility while still maintaining a low flexural modulus and good impact resistance. This resin is well-suited for applications like living hinges where superior elongation is essential.

AFP3600 (~82 Shore D)

This clear material can be easily pigmented, provides good heat resistance, and provides enough flexibility for small parts like clips and snap fits. Lenses, housings, backlight applications, and both clear and frosted components are often made with this urethane.

PT8958 (85 Shore D)

This material is most often used to create medium or large medical components that must be both MRI-transparent and flame-retardant.

RC 79D (85 Shore D ±5)

Also MRI-transparent and flame-retardant, this tough, impact-resistant material is often a good fit for smaller medical devices and assemblies.

Urethane Elastomers (Shore A Resins)

Shore A materials are softer than the rigid shore D materials, providing greater flex and, often, good tear strength. At one end of the material spectrum, 0 Shore A refers to soft, gel-like materials, while semi-rigid plastics measure 90 or 95 Shore A.

Common shore A materials include:

E1005AL (5 Shore A)

This extra soft elastomer is an excellent all-around soft rubber that’s easy to dye and offers good tensile and tear strength. For this reason, it’s commonly used to create medical training models, special effects, and props.

E1015AL (15 Shore A)

Similar to E1005AL, but with slightly increased rigidity, this elastomer is excellent for creating soft rubber grips and stretchable linings.

E1040AL (40 Shore A)

This medium-soft resin is similar in hardness to a standard pencil eraser, making it well suited for overmolding and keypads.

E1060AL (60 Shore A)

This medium-hard material is a good general purpose elastomer often used to create bellows, boots, and overmolded components.

E1070 AB (70 Shore A)

Comparable to the hardness of automotive tires, this material’s blend of durability and wear resistance is also ideal for cable connectors.

E1095AB (95 Shore A)

This material offers good abrasion and tear resistance, and is often used to manufacture shopping cart wheels, rollers, and bumpers.

Each of these thermoplastic elastomer resins are compliant with the European Union’s Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH) and the Restriction of Hazardous Substances (RoHS) standards.

Silicones

Silicones are softer than shore A materials and are used to create a select few kinds of parts; however, they are commonly used to create the molds by which end-use parts are cast. This is especially true when using the cast urethane molding process for bridge tooling, an interim step that allows production to begin while the injection molds and other hard tooling is machined and finalized. Castings for bridge tooling can also be done in urethane, foam, or metal.

Common silicones include:

AFS15 (15 Shore A)

A soft rubber, this silicone is often used in applications like ink stamp pads and pressure pads that require good flexibility.

AFS30 (30 Shore A)

A little firmer than AFS15, this casting silicone can be used in mold-making and to encapsulate other components.

AFS40 (40 Shore A)

This medium-soft silicone makes excellent buttons and keypads, while also providing good water resistance.

AFS60 (60 Shore A)

This medium-hard rubber works well for mold-making and applications that require encapsulating.

Each of these silicones can also be used to create viable components like gaskets and seals in varying hardnesses.

Leverage the Benefits of These Common Urethane Casting Materials Today

Urethane casting is a useful method of manufacturing for a number of reasons. One, it’s fast and generally quite cost-effective. Two, it produces high-quality, end-use parts. Three, you have a huge variety of polyurethane elastomer resins at your fingertips with which to work. However, having so many options available can sometimes be overwhelming — how can you determine how subtle differences between materials will affect the longevity and performance of your part down the line?

The good news is that partnering with a skilled, on-demand manufacturer SyBridge takes the hassle out of material selection, design, and production. In fact, our approach has been shown to cut urethane casting costs by up to 60%. If you’re interested in learning more about how our flexible production methods can bring your plans to life — on time and on budget — contact us today.