Originally published on fastradius.com on October 12, 2020

The best parts aren’t made by chance — they’re the product of hours of testing and refining designs before production even begins. Prototyping plays a key role in the product design process, helping engineers detect potential flaws or issues in a part’s design early on. With this information, product teams can avoid costly, time-consuming design revisions while improving the quality of the final part.

The advent of 3D printing technologies enabled faster prototyping that is more cost-effective and more accurate. Two of the most common — and most effective — additive manufacturing methods for prototyping are fused deposition modeling (FDM) and stereolithography (SLA), each of which presents product teams with a unique set of benefits and ideal use cases.

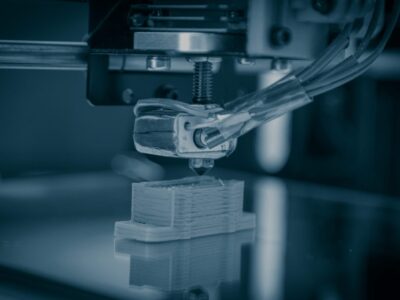

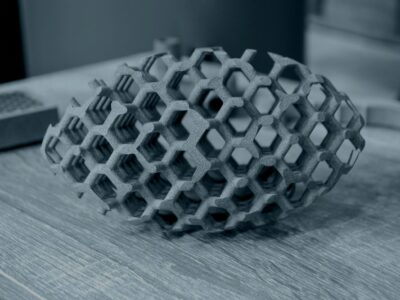

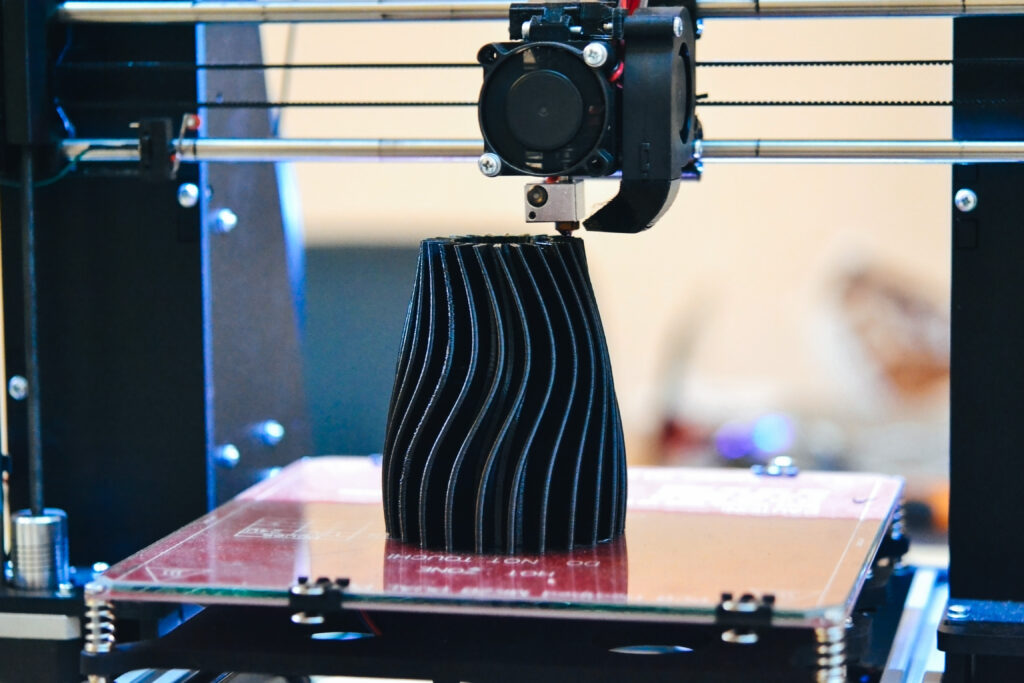

Key considerations for fused deposition modeling (FDM)

FDM, the most common method of 3D printing, uses a heated nozzle to print lines of molten thermoplastic filaments, creating a part one layer of material at a time. The low cost of materials and speed of automated production makes the process ideal for creating proof-of-concept models and quickly prototyping large, simple parts.

One key limitation of FDM is that part resolution is partially determined by the size of the extrusion nozzle. This extrusion process results in visible gaps around the perimeter of each layer due to the rounded edges of the extruded material. This process also results in anisotropic mechanical properties because the bond between layers is inherently weaker than the base material itself.. As such, FDM generally isn’t ideal for producing parts with intricate details or smooth surface finishes.

Simple, unsupported FDM prints often require little to no post-processing. However, because of the lower surface resolution necessitated by FDM, supported parts or prototypes that demonstrate surface finish will need to be post-processed manually, which increases both the cost and time of production.

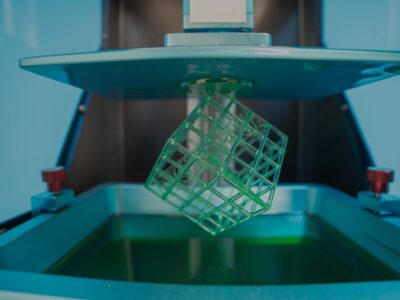

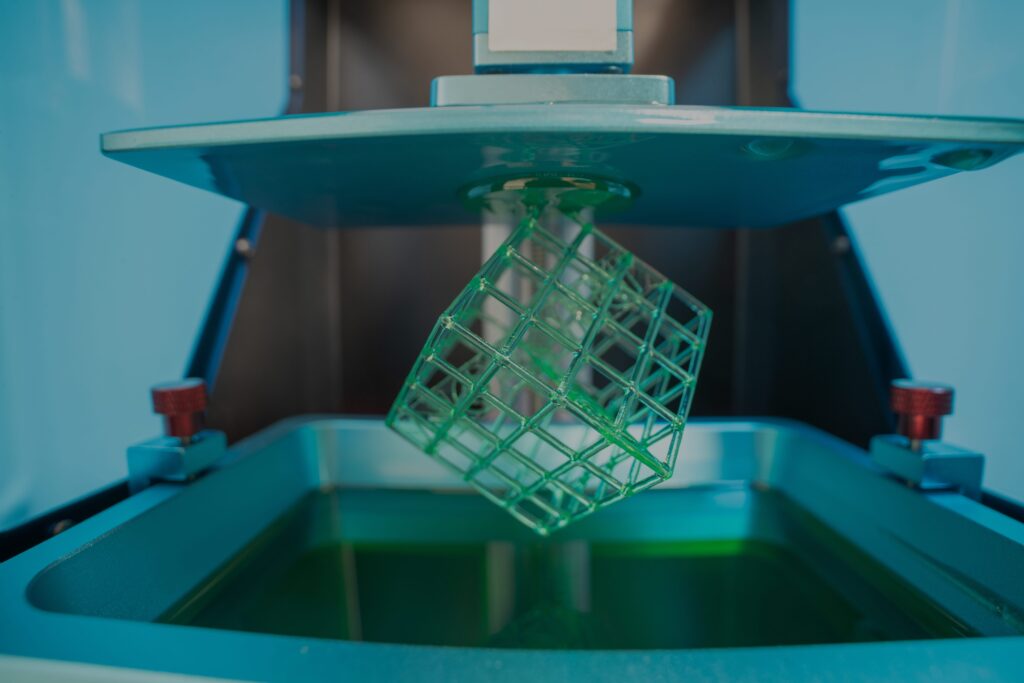

Key considerations for stereolithography (SLA)

SLA, on the other hand, uses a laser to cure and harden liquid resin into plastic shapes. This process, called photopolymerization, is one of the oldest forms of 3D printing technology. FDM processes rely on mechanical bonding between layers after melting and solidification of the filament.

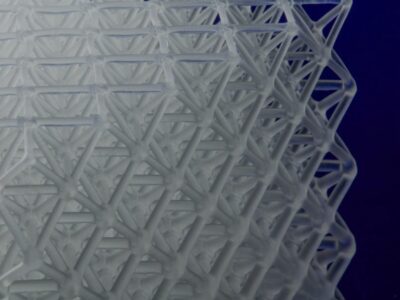

The precision of laser-curing provides significant benefits. Not only does the process enable more intricate details and features to be incorporated into the part design; it also allows manufacturers to more reliably and consistently produce precise and accurate parts with smooth, high-quality surface finishes. Furthermore, by relying on photopolymerization rather than a primarily thermal process, SLA-printed parts are less susceptible to thermal expansion or contraction during and after production.

SLA resins can provide a variety of different mechanical, physical, and thermal properties comparable to many commonly used industrial thermoplastics, making the process well-suited for producing functional prototypes that test or demonstrate desired material properties. However, SLA-printed parts tend to be sensitive to long exposure to UV light, and will need stabilizers if used in applications where they are exposed to the elements.

Discover the manufacturing process best-suited for specific prototypes

The ideal 3D printing process for prototyping will depend on a number of factors. If resolution, accuracy, and surface finish are highly important — or if product teams are looking to create fully functional prototypes — then SLA is likely the strongest choice. However, if teams are looking to create a rapid, low-cost proof-of-concept, then FDM printing will likely be the more economical option.

Partnering with an on-demand digital manufacturer like SyBridge optimizes the product development process. Our team of seasoned designers, engineers, technologists, and advisors bring decades of expertise to each project, working closely with customers to refine part design, prototype quickly and effectively, manufacture parts in custom volumes, and ensure that orders are fulfilled on schedule. Contact us today.